The Mizer’s Ruin – Eastern Redcedar Design-Build Microdwelling

The Mizer’s Ruin – Eastern Redcedar Design-Build Microdwelling

Location

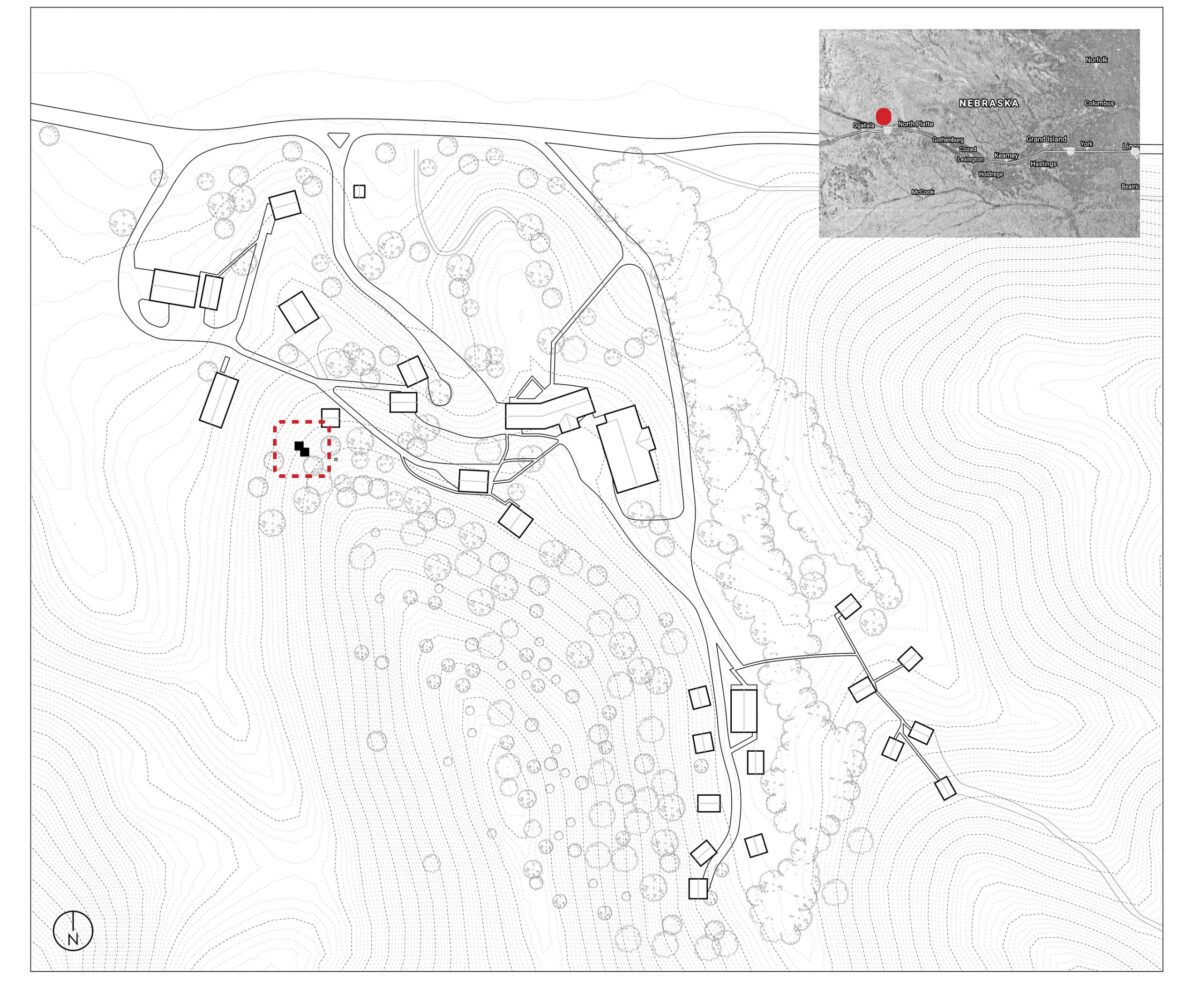

Ogallala Nebraska

Clients

The Nebraska Environmental Trust

Partners

Jon Garbisch – CPBS Associate Director

Ken Kilzer – Olsson Associates

Nick Limpach – Morrissey Engineering

Bill McMillan – Sandhills Plumbing

Adam Smith – The Nebraska Forest Service

Students

Daisy Alarcon, Wijdan Al Mamari, Jarod Bengtson, Vy Cao, Karolayn Chavez , Trey Erwin, Doug Rief, Erin Applegate, Martha Boulware, Ian Carroll, Elena Felix, Chloe Gilbert, Cody Kleinschmit, Dennis States, Shayla Jorgenson, Grant Wolfe, Matt Gager, Dana Howerter, Cort Johnson, Reece Kremers, , Sydney Reedy, Pia Schulenberg, Kyra Stradley, Alec Burke, Ian Jones, Christopher Lee Tran Nguyen, Elijah Velinsky, Alex Martino, Austin Wahl, Trever Zelenka, , Haley Herman, Alyssa Villareal.

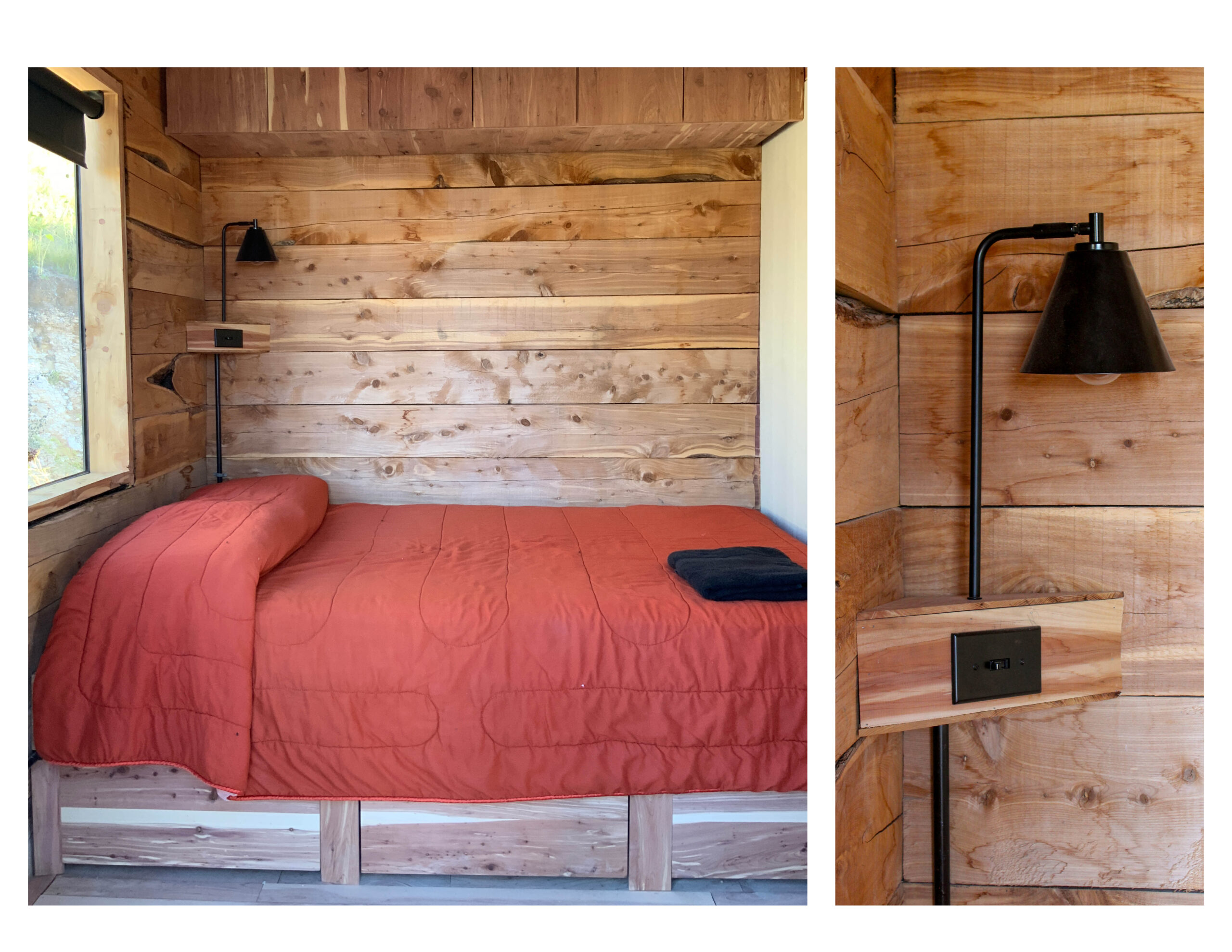

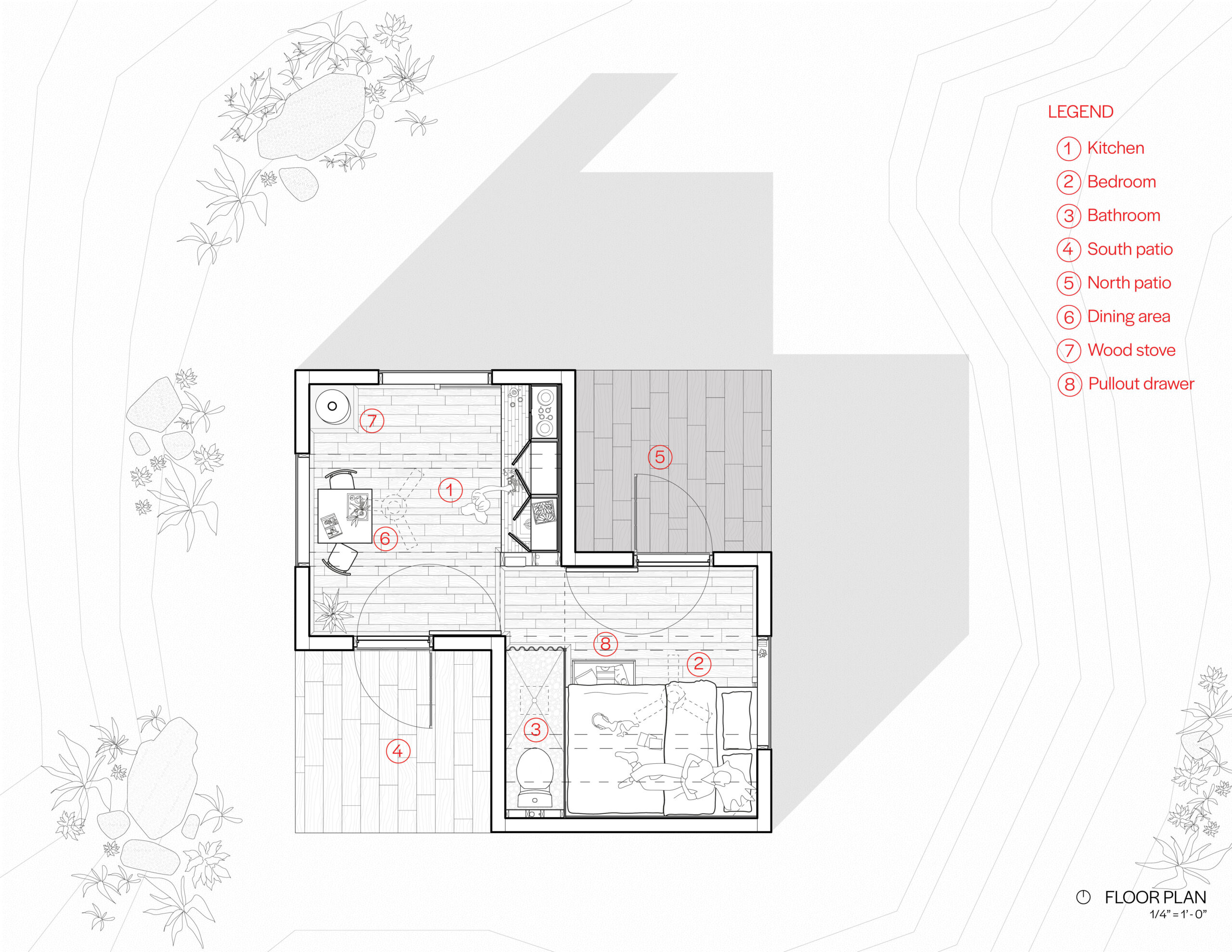

The Mizer’s Ruin is a 190 sq ft micro-dwelling that provides accommodation for researchers, visiting faculty and staff at UNL’s Cedar Point Bio Station. It develops a low-carbon fabrication system that directly engages with local forestry production and wildfire mitigation.

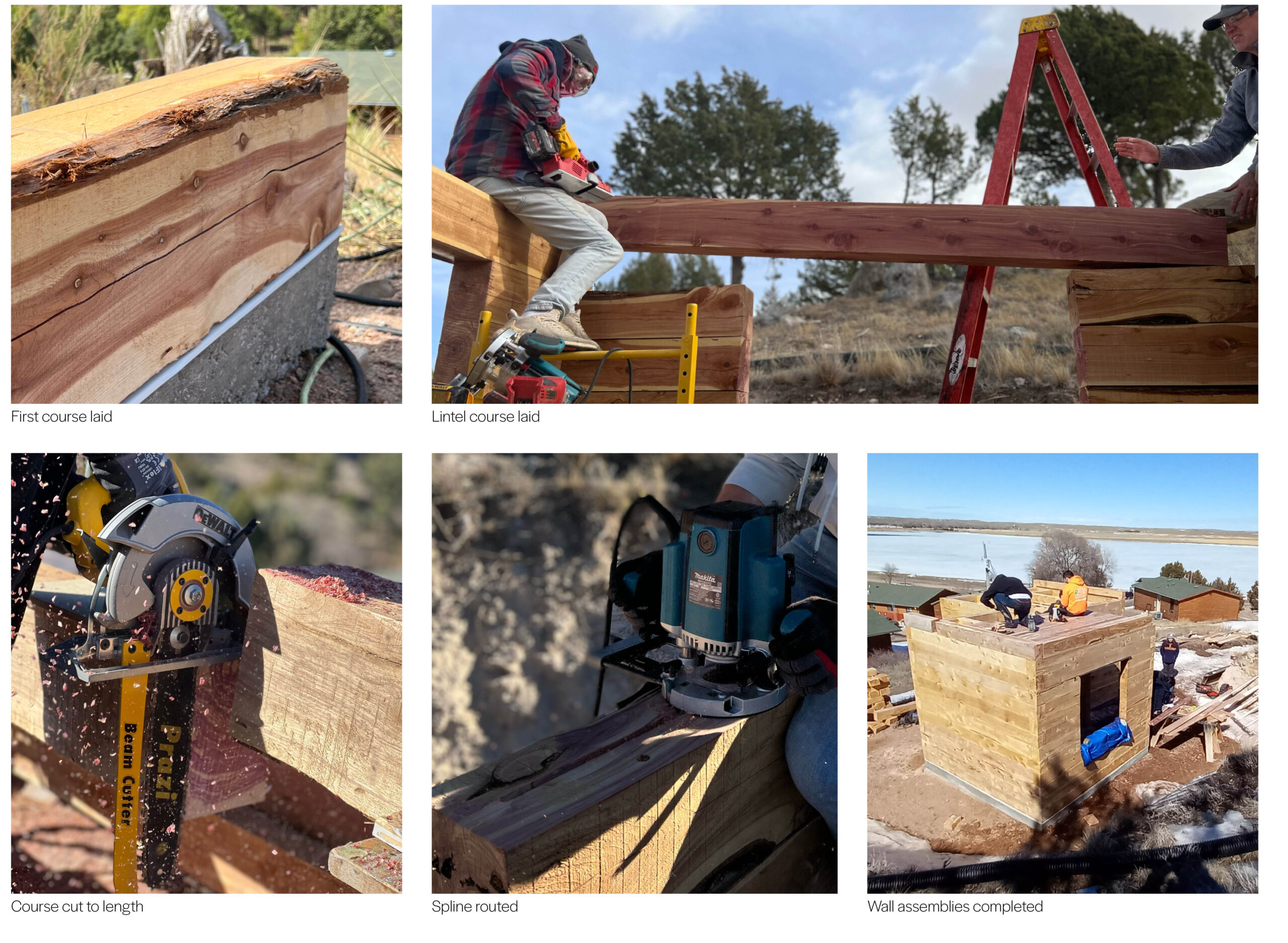

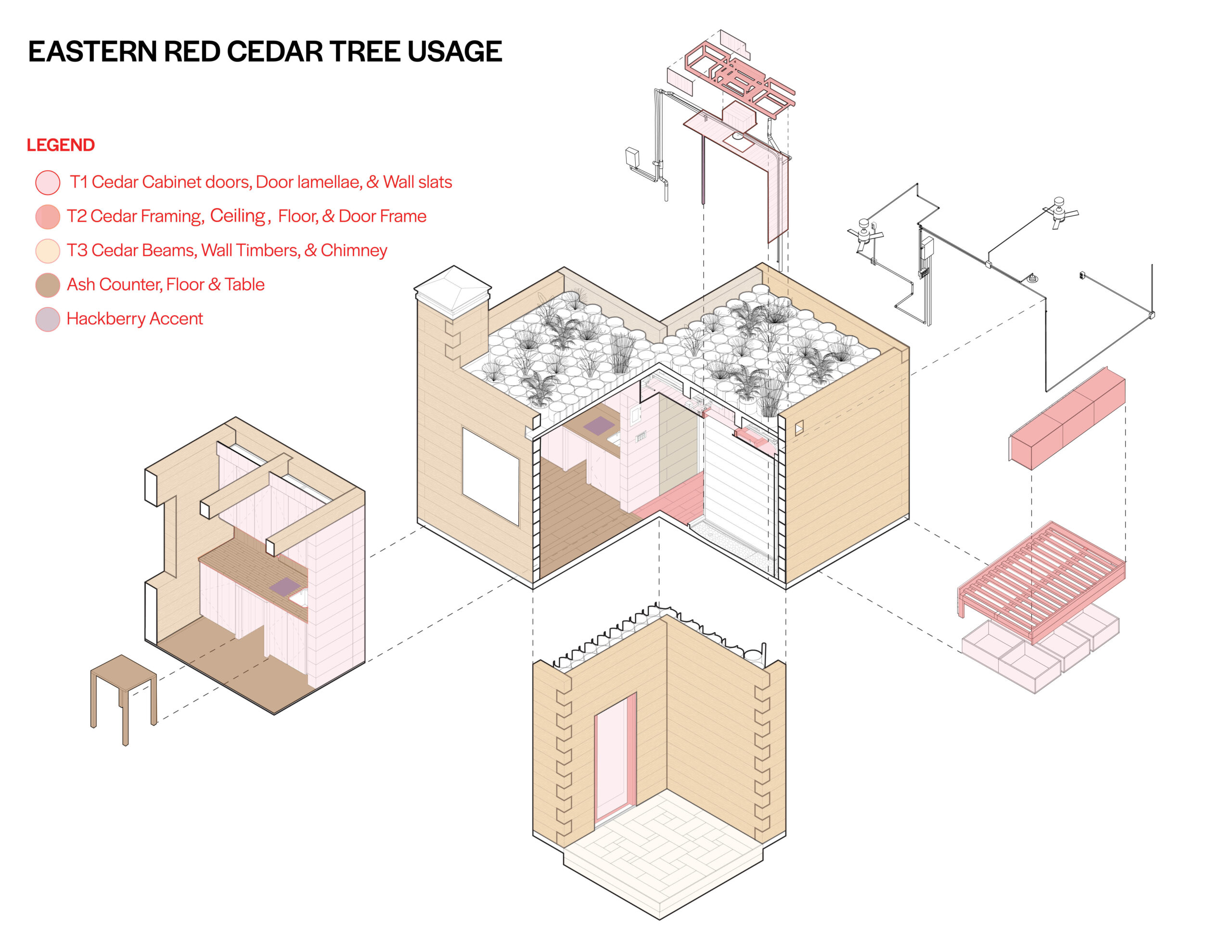

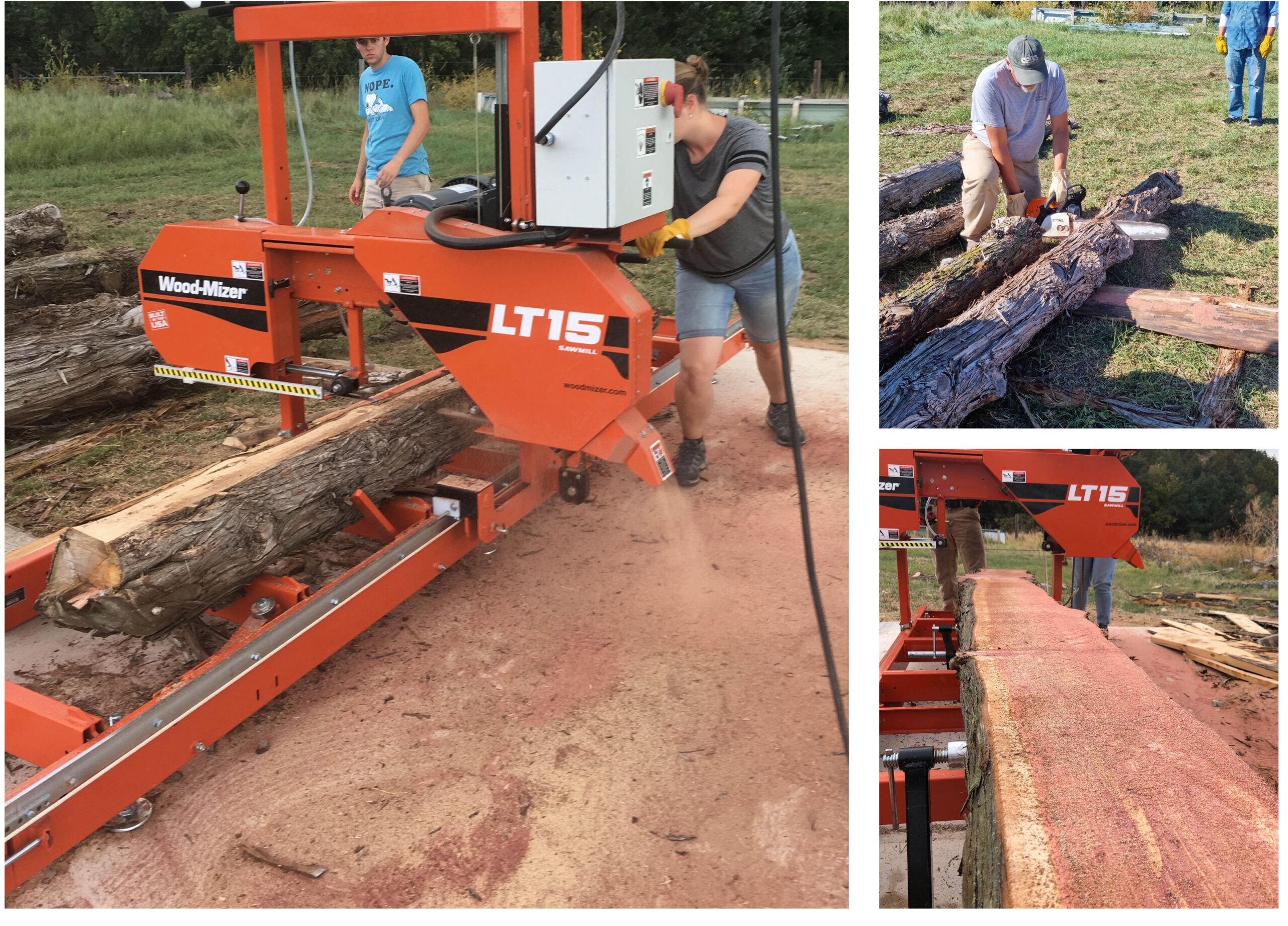

It offers a response to concerns about the impact of eastern redcedar in Nebraska. These concerns are divided between those who consider it an invasive problem and organizations looking for an appropriate use of local resources. In response, UNL’s landscape management services at CPBS have implemented a harvesting program that strategically removes trees as they reach maturity. These trees are then be milled onsite (using the mobile wood Mizer) and dried in preparation for potential construction.

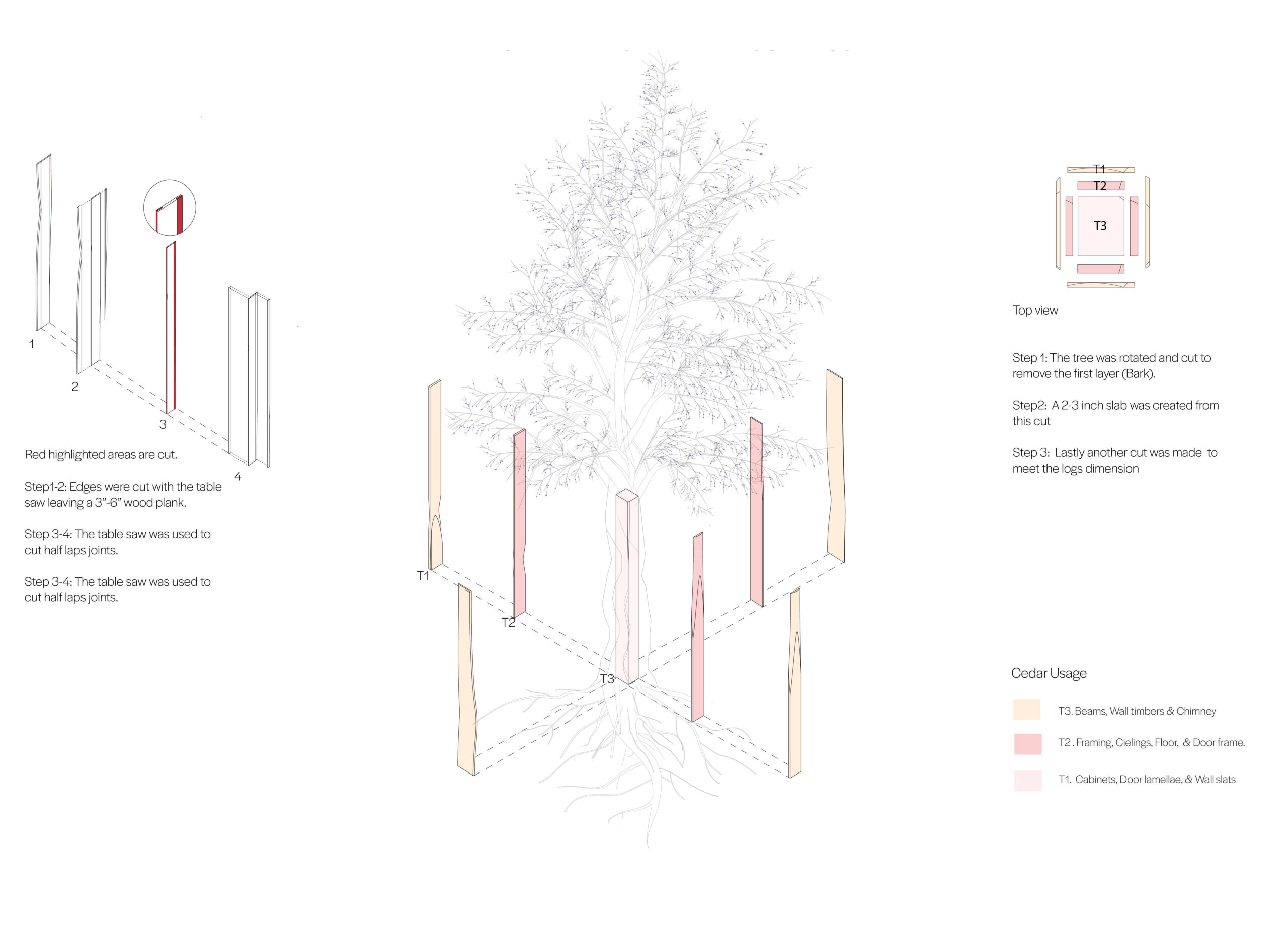

The cabin’s design is a response to the dimensional constraints of the tree and the technological limitations of site milling and construction. The plan comprises two 10′ x 10’ squares (max length of cedar stock) arranged as a simple log cabin construction to provide basic sleeping and study accommodation.

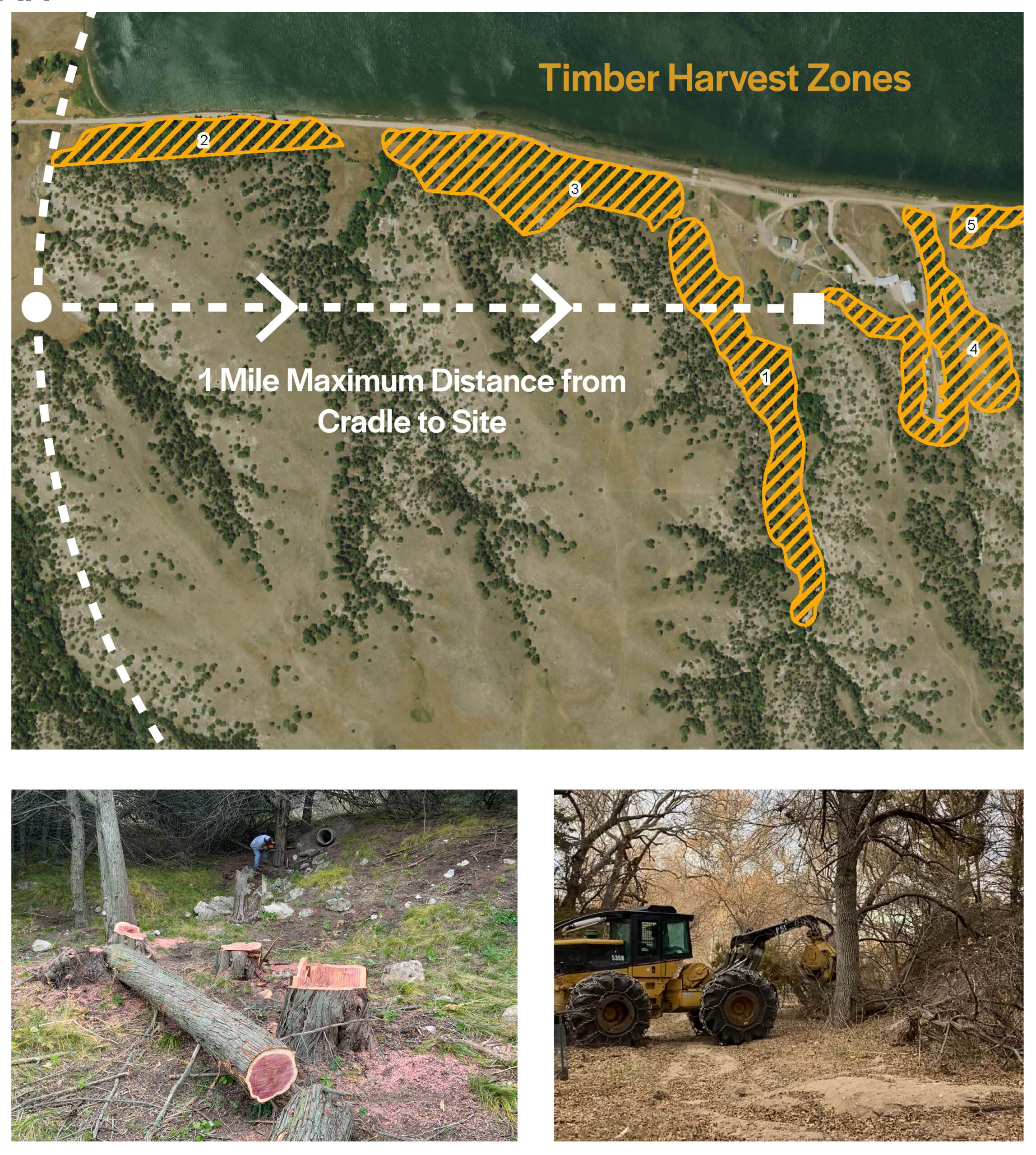

The issue of forestry management is central to the constraints of the project. Our intervention began by working with the state forestry service to establish new terms for their Forest Stewardship Plan in the canyons adjacent to our site.

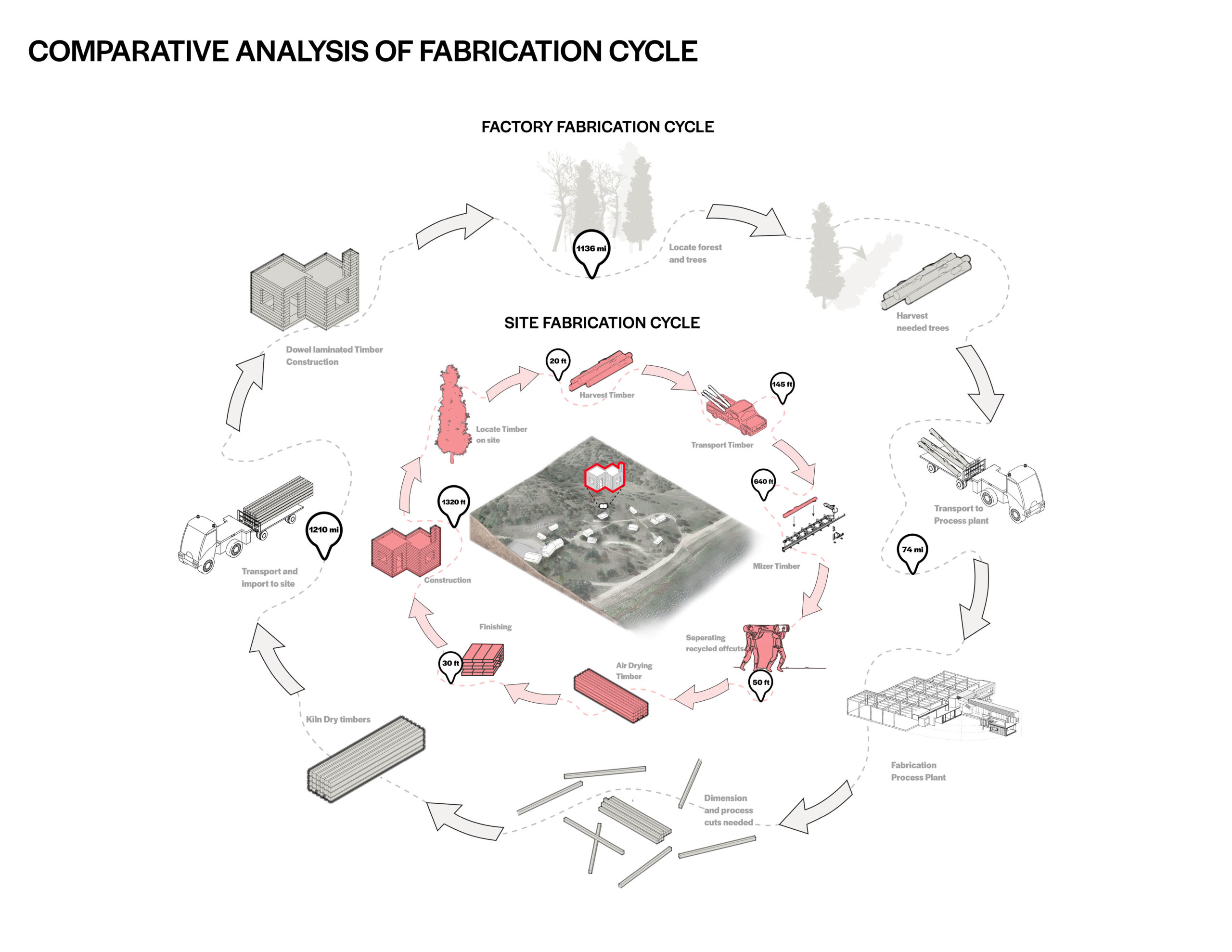

The extent of the forestry harvesting plan was also determined by the areas of the site most vulnerable to wildfires and also determined by the outer radius of all our timber supplies. It allowed us to explore a mass timber construction system constrained by a maximum radius of 1 mile from “cradle to the site”. This effectively meant that most of the stages 1-5 of the Whole Life Carbon Assessment were easily within walking distance of our building.

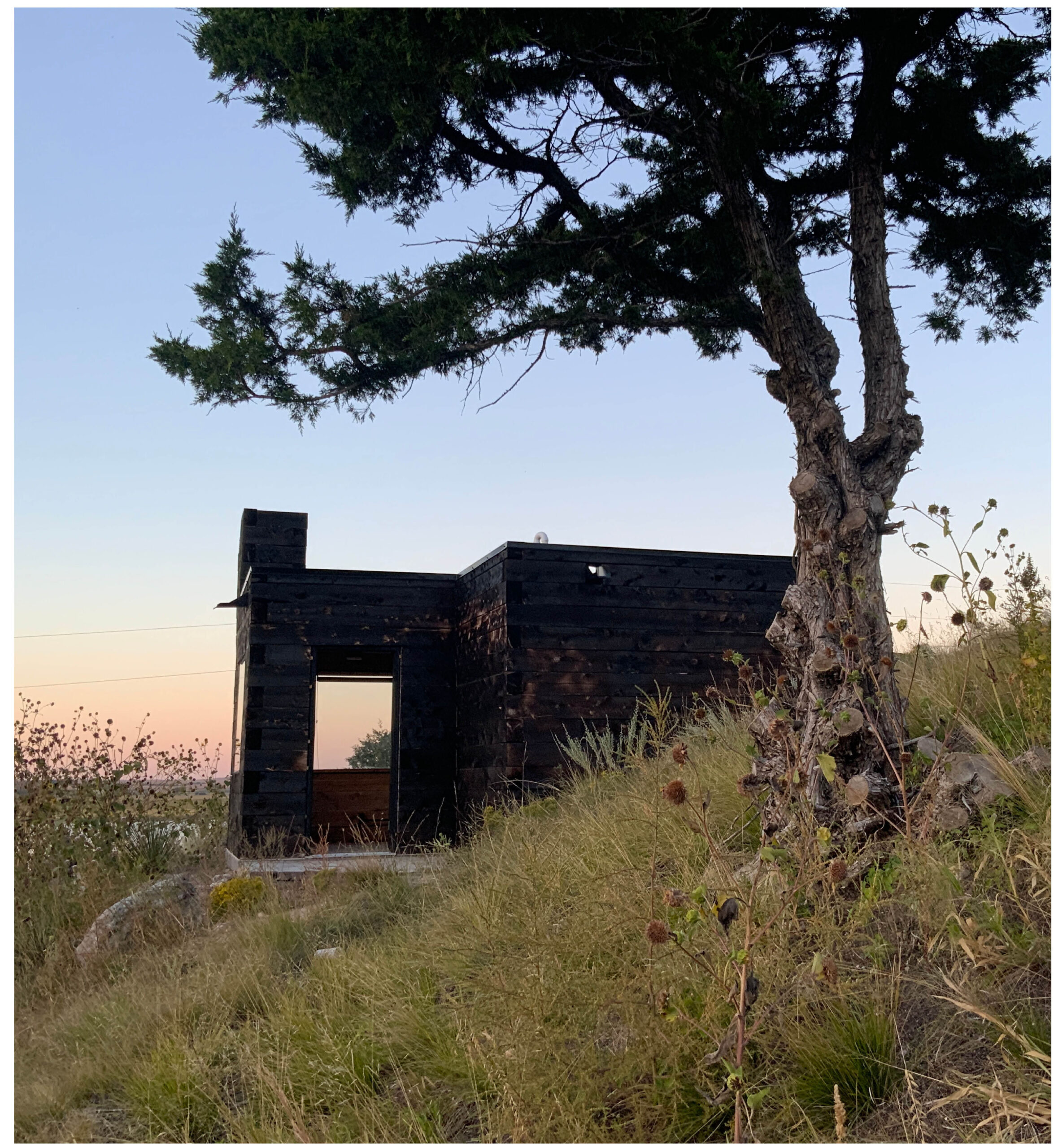

The cedar is finished with a Shou-Sugi-Ban charred surface to project exterior walls and reduce maintenance costs.

The phasing of the project is arranged to coincide with seasonal activities and the behaviour of the wood between early summer and winter. Our strategy was to harvest for drying and carpentry in the spring of 2022 over the next two years. Although charring of the exterior was planned for “burn days” after the first snowfall favourably damp conditions allowed us to complete the burning as late as April in 2023.

The project results from a circular process of design-build activities that began with an inquiry into regional agricultural practices and field studies of local forestry that led to grant funding.. The project accommodated successive material explorations, speculative making, and in-the-field experience-based learning of lumber production. Knowledge from these activities was applied to innovative construction practices that focused on location-based mass-timber assembly systems. The Mizer’s Ruin is a fully serviced building that provides year-round accommodation.

The proportions of the building are determined by the constraints of eastern red cedar harvesting and local milling. It provides for the selective extraction of saw logs that we determined to be useful for the primary structure and components of the interiors. In effect the extent of the plan geometry is determined by the maximum average length of usable sawlog (around 17’) from which we could produce 10’ lengths.